Weave-a-long lessons in stash busting.

June 6th to July 17th

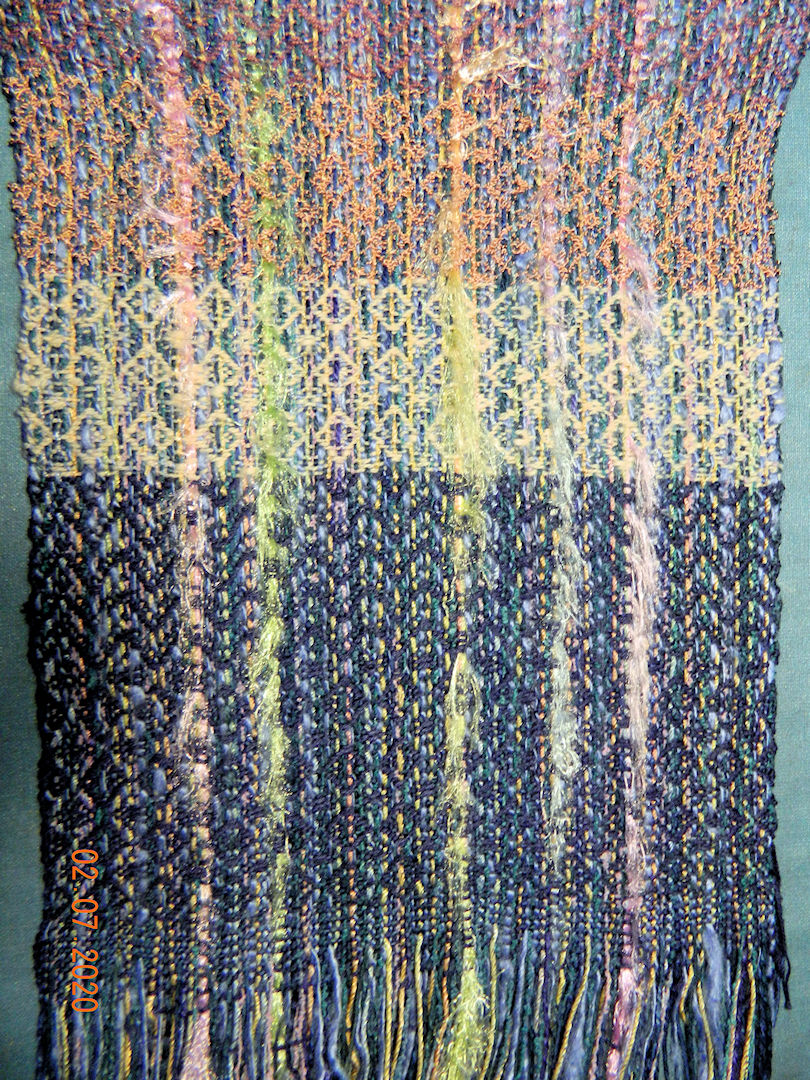

Click image for enlargement.

First I played with colours.

(09:06:2020)

There were weekly on-line lessons by Tien and Janet. Some people starting winding warps right away.

I rejected some of the first yarns and tried again with this batch.

(10:06:2020)

(10:06:2020)

This is what was left after the warp had been wound. The weft is a cotton slub. The green and pink is silk boucle. The pale blue, dark blue-green and the variegated peach-blue-pink are rayon. Plus a little bit of polyester eyelash.

(02:07:2020)

Then I went to the computer and played with weaving drafts. This was version number 7. At that point I was planning to use a dark weft.

(11:06:2020)

(24:06:2020)

The finished warp, all tied up and ready to go to the loom.

(24:06:2020)

It started going over a beam up at ceiling level but I forgot to take a picture then. Here winding on is almost finished.

(27:06:2020)

The other end of the loom - all wound on, the lease sticks transferred behind the reed and loops cut so the reed can be removed. All "ready" for threading - except that weavers will see the problem here!

(27:06:2020)

Allan made the handy lease stick holders for this loom several years ago.

(28:06:2020)

Threading is under way.

(28:06:2020)

(30:06:2020)

I wove a sample with four different wefts and decided that I liked the pale one in the centre best. This had been cut off, washed, and pressed to see the changes brought about by "wet finishing."

I also identified a couple of errors - a missed dent in the reed and a threading error that were fixed before tying it back on again.

(02:07:2020)

Weaving the scarf is finally under way.

(09:07:2020)

(10:07:2020)

Finished and ready to be cut off. The last pattern repeat was done with fine weft so it can be turned in for a hem.

(14:07:2020)

(17:07:2020)

All finished and ready to be modeled by Neil the Bear - only two weeks late.

(17:07:2020)

(17:07:2020)

A close up showing both sides.

There is enough warp left on the loom for another scarf - probably with a different weft and treadling pattern. You wouldn't want two of anything the same!

(17:07:2020)

| Click the Home button below to return to the main button menu. |

|