New Loom (starting Sept 19)

|

Trapeze, for putting on warps without help. Check out http://LauraFry.ca for an explanation of what it does.

(July 10, 2008)

|

|

|

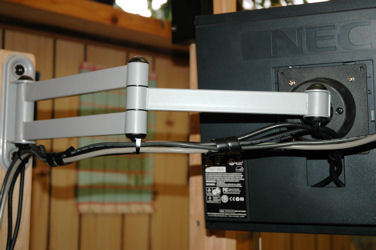

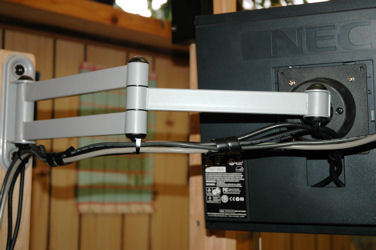

Arm

|

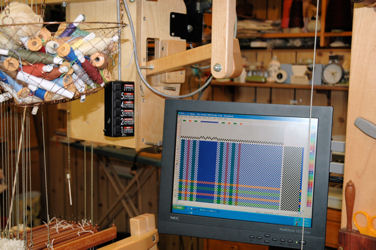

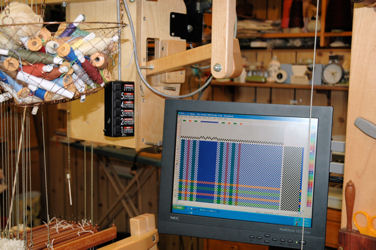

Whole setup

|

Working side

|

An other addition to the loom. On the left, with the six bolts is a bracket to hold an articulated arm for the monitor

(March 27)

Mouse over thumbnails

|

|

The rare earth magnet trips the micro switch (the sort used in door alarm systems). When tripped it sets off a annoying buzzer mounted at the end of the red wire, that alerts Sheila to raise the cloth take up weight before it hits bottom and stops doing it's job.

(Nov 25, 2007)

|

|

|

Dobby mounting.

|

Spare parts.

It is always good to have left over parts after assembling something!

(Nov 03, 2007)

|

|

|

Real weaving has been done! A couple of adjustments to the dobby and to the cloth storage roller and way we go.

|

Computer in background. CompuDobby is up and running.

(Oct 10, 2007)

|

|

|

The first shot and the first beat!

|

The towels keep the weavers arms from being sanded by the breast beam. It is sand paper covered to "catch" the cloth as it is formed and keep the whole thing tight.

(Oct 10, 2007)

|

|

|

Threading at last. Oct 6, 2007

|

A mechanical computer! This is a "dobby" that controls which shafts are lifted for each "shot" of the weft threads. They are hard to see, but there are small pins, one for each shaft, that cause the cords that lift the shafts to be caught as the weaver stomps on the treadles.

(Oct 6, 2007)

|

|

So the new loom has not been threaded yet, but has it's first mod! Change the right hand breast beam bracket so the beam can be removed without having to use wrenches etc.

(Oct 6, 2007)

|

|

|

Laura Fry, happened to stop by on her way home from a spinning workshop, and got put to work.

This is about 10:00 pm on October 1! Up, and partianly warpped. One small problem with the shafts to resolve before threading can begin.

(Oct 2, 2007)

|

|

Construction crew got to work around noon on October 1 (note start date).

|

|

|

Assembly went fairly smooth, other than one frame section that had to be rotated, and the back beam having to be moved after every thing was squared up and locked down.

(Oct 2, 2007)

|

|

So the loom made it home with out problem and was stacked in the "loom Room"

|

A couple of weeks later, the existing loom (spool racks, benches, cat beds, stools etc) moved to the laundry room, to make space for construction.

(Oct 2, 2007)

|

|

|

We had to wrap and pad it for the drive back over 2500 kilometres of highway. Turned out the water proofing with tarps was a good idea as it rained every day for the trip home.

|

The load was not enough! When we tried to "bungy" it was not tight and it "flapped" in the road breeze all the way home.

(Sept 19, 2007)

|

|

You might think of this as a "loom kit". The job started by having to finish taking it apart so that it would load on the truck.

(Sept 19, 2007)

|

|

|

Having never paid much attention as to how these things go together, it was a challenge to finish taking it apart for loading

|

|

I Un-assembled and bundled parts as they came off with 6 inch wide stretch wrap. I LOVE THAT STUFF!

|

|

|

Tried to box up related parts as they came off the frames.

|

|

Some things were just not worth pulling apart, like the headle return on the right of this picture.

|

|

|

|

|